An impact driver, also known as an impact drill, is a tool or a device that can be used in order to drive screws inside at a rapid pace.

These tools usually come either corded or cordless and are mostly used along with other power tools.

There are many brands that will serve you with a decent quality impact tool. However, none of these brands can keep up with the value brought forward by the DeWalt impact driver.

You’ll get years of consistent performance and utility from this unit as long as you keep it maintained.

It is common knowledge that even the best devices can fail under rough usage and ignored maintenance.

So, if you wish to avoid the same outcome, be sure to educate yourself on the basic maintenance needs of the unit. That way, you won’t have to worry about hardware issues.

How to Fix DeWalt Impact Driver Not Holding Bit?

Impact drivers, just like any other tools, can also run into issues every now and then.

That being said, we have been hearing plenty of user complaints about experiencing issues with their DeWalt impact drivers.

One of the most popular issues amongst them is that their DeWalt impact driver is not holding a bit.

This issue can be incredibly annoying as you won’t be able to engage the system at all without the bit holding section.

Sadly, there are a ton of things that can go wrong and play into this situation with the DeWalt impact driver.

In case you have also been facing a similar issue, then this article should help you!

Through the article, we will be taking a look at some of the most effective ways you can fix the issue for good! Here’s everything to know:

- Replace the Spring

In case you aren’t aware, there’s a small spring present inside every DeWalt impact driver that is responsible for helping in holding down the bit.

However, the spring may get faulty or broken over time which then requires you to replace the specific part.

Luckily, replacing the spring inside the impact driver is quite easy, and even you can do it yourself.

Simply go to DeWalt service net, where you can enter your exact model number and see its breakdown.

Here, you can check how to get the spring off of your impact driver. Once you do so, you can easily replace it with a newer one.

Also, there should be a steel ball located near the spring. In case replacing the spring does not help, we recommend you replace the steel ball as well.

- Try A Different Bit

Sometimes, the issue is not with the unit but with the bit itself. So, you will need to eliminate this possibility by checking the bit for damage.

As long as you’re sure that the spring is in good shape and the purchase of the impact driver was recent, then getting a new bit will do you well.

Just be sure to insert it properly, and don’t ram in the bit against the gears.

Even if your chuck is in good shape, the gears behind the chuck can get damaged if you’re rough with the device. So, be sure to be gentle here and then tighten up the chuck.

If that fixes your issue, then you’ll know for sure that the chuck is not to blame here, and you need to get a new bit.

This replacement will be far more affordable than replacing the impact driver or any of its components. So, pray that it is the bit that is to blame here and not chuck.

On the other hand, if you’re still stuck in the same errors and can’t seem to figure out the issue, then the problem is more linked to the chuck and not your bit.

In that case, you’re not left with many options but to get a new chuck. Furthermore, you should hire an expert for this replacement.

- Time To Get A New Chuck

Nine times out of ten, the issue will be fixed as soon as you replace the spring and then put the bit back into the unit.

If you’re sure that there are no serious issues with the bit itself, a new chuck will serve you perfectly.

This is especially true if you’ve been using this machine for a few years now. So, if the user has been a bit rough and you’re not too sure about the unit status, getting a new one is the only real move.

There are no other methods that can be used to get through these errors.

All you have to do here is to reach out to the dealer about the situation with the worn chuck.

He will ask you for the make and model of the impact tool, and then a replacement will be dispatched.

The best thing here is that you won’t have to go over the budget and to get a new unit is pretty affordable.

So, be sure to reach out to an expert, and he will guide you on what chuck will best suit your impact driver. From there, the adjustment is pretty easy.

- Try Releasing the Bit

Another thing that you can do is to release the bit that might already be inside the holder. To do this, you will have to hold the chuck by its sleeve.

Afterward, put your drill in reverse mode while making sure you have set it to high torque. All you need to do next is to go full speed, which should automatically release the bit.

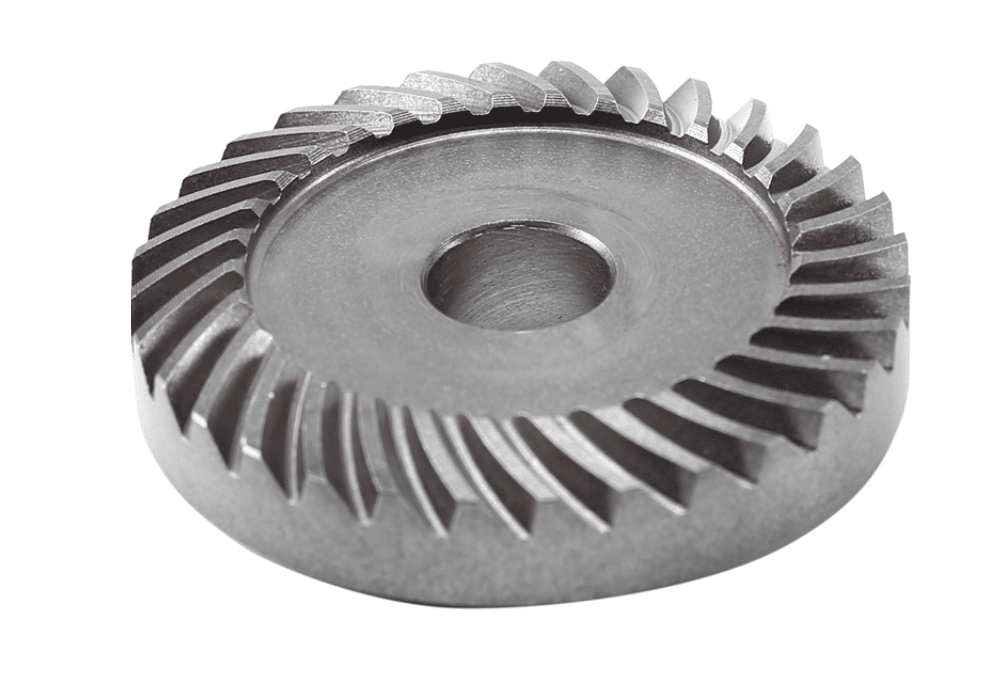

- The Gears Might Be Damaged

Sometimes, it is the gears and not the chuck itself that are damaged, and you will have to isolate this error by checking the unit thoroughly.

There are no quick methods that can be used here, and you need to make sure to clean up the unit properly before looking at the condition of the gears.

If you do find the gears to be damaged, then you’re out of luck here. You can’t do anything on your end to fix the damaged gear and will have to go through the replacement.

However, we suggest that you let a professional take over this issue.

Replacing the gears is not always the easiest, and seeking office support will save you a lot of hassle in the long run.

It all comes down to your budget, and the only thing that you will have to spare money for is the replacement fees.

Hopefully, you won’t have to go through much hassle to go through the fix. You’ll get an amazing performance after the gears have been replaced, so be sure to fix this issue quickly.

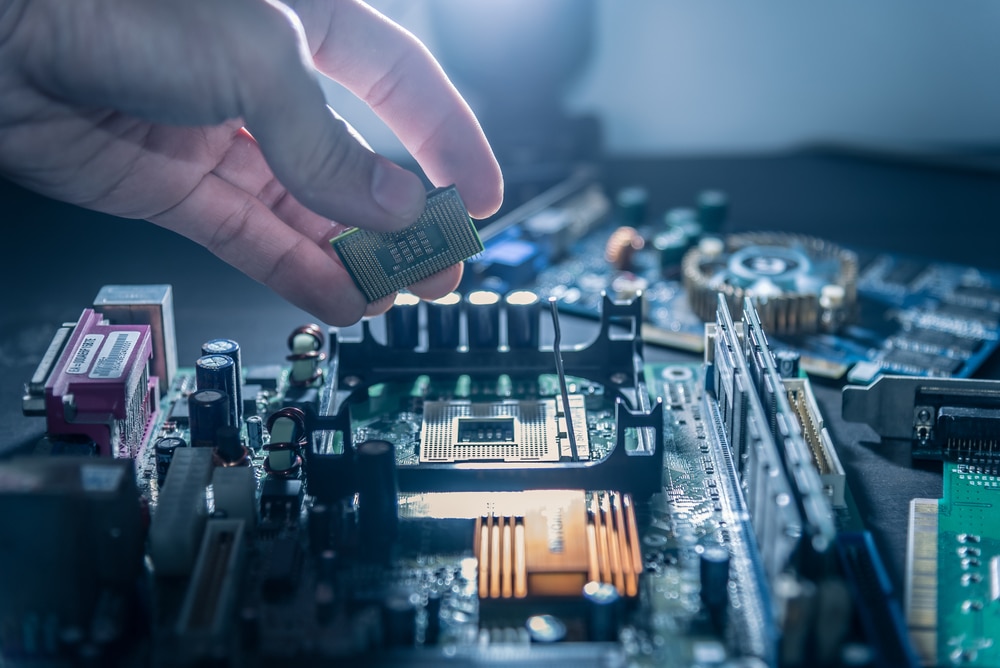

- Getting it Checked

In case you haven’t had any luck so far, then the last thing that you can do is to get the components checked and replaced by a professional.

Alternatively, you can also try contacting the support service as well.

The Bottom Line:

While the DeWalt impact driver not holding the bit is quite a common issue, it can be easily resolved by simply replacing a spring, at least in most cases.

There are certainly other cases where the issue might be caused due to other components.

As long as you’re sure that the hardware status of the unit is in good shape, you will be able to get through the issue pretty quickly.

However, if you’re not too sure about the unit, the better idea here is to claim the warranty.

The deal on the DeWalt systems is pretty great and will keep you served with some of the best units on the market.

So, be sure to keep that in mind as you try to get your hands on a fresh replacement. It all comes down to how you’re planning on maneuvering through the issue.

All you’ll have to show here is a valid proof of purchase, and the dealer will take it from there.

So, if you’re sure that the unit is defective, be sure to contact the dealer. Hopefully, you will have the new unit within the same week.