DeWalt makes some of the best possible tools in the world, and they are perfectly great to get you the right choice of having a convenient experience with all the different sorts of work needs you might have.

It is the go-to option for everyone from an expert to an average joe.

Not only that, but the DeWalt impact drivers are a great blessing for all those who need to ensure that they can get those self-tapping screws into wood since they need rotation and power at the same time to make it all work for them.

As long as you’re keeping track of the maintenance, it is not that hard to keep the DeWalt tools in good condition for decades.

DeWalt Impact Driver Not Impacting

A bit of your time can make all the difference, and you should reach out to the professionals working at the support center to educate yourself on the proper care routine.

Yet, if the impact driver is just screwing and not impacting, that can be troublesome, and a few ways to get this fixed and sorted out optimally would be:

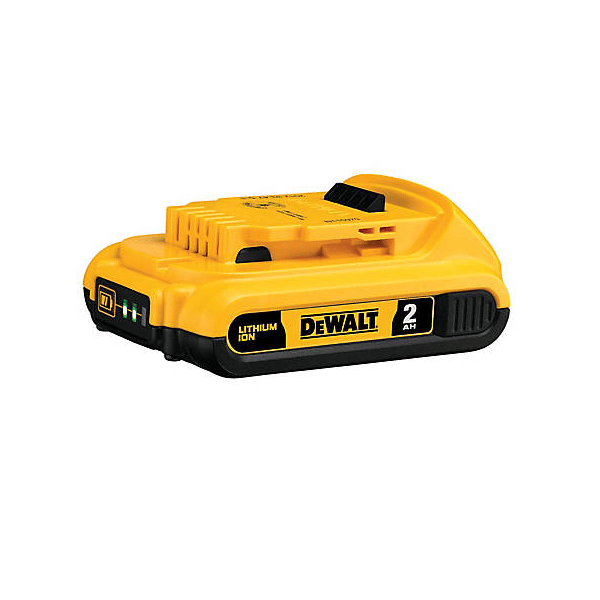

- Check the Battery

Most of the time, the problem occurs on the cordless impact drivers from DeWalt, and you will need to ensure that you are sorting it out perfectly to get the perfection that you might have been seeking with the work at hand.

To make that sure, you will need to check the battery power and health. If the batteries are not in the right health, they might not be able to provide the right power and current to all the components, and you will have to ensure that you are replacing the battery.

Yet, another problem might be a low charge on the battery, and if your battery health is fine, you will need to ensure that you get the battery fully charged.

That should help you out perfectly to sort out this problem, and you will not have to worry about it again either.

- Check Fuses

Once you get that sorted out and the problem is still there, you will need to make it right by checking on the fuses.

There are several fuses on the impact driver, and you should be ensuring that you are fixing it up properly.

You need to inspect the fuse for the impact motor on the Impact driver.

If the fuse is blown, you will have to replace that with a new one in order to ensure that you can get it sorted out in the perfect manner, and that will ensure the right experience for you that you might be looking for on the impact driver.

- Allow The Unit To Cool Down

At this point, you should allow the unit to cool down. This is especially true if you’ve been using the unit on a demanding project without any breaks.

While the DeWalt systems are pretty robust, you will still need to take a few breaks here and there to get the desired response.

Being harsh on your tools is never a good idea as you will lose the efficiency status and won’t get anything out of the device.

So, all that you need to do is to allow the unit to cool down and then proceed with the setup accordingly.

If the issue is fixed, now might be a good idea to think about properties storing the unit. It can be a struggle to get the units to work properly when there are issues with the storage.

So, find a dry and cool spot for your tools and you will not run into these issues as often.

- Check the Direction Switch

Sometimes, this issue can present itself according to the orientation of the direction switch.

Owners have pointed out that the direction switch can rest in the middle and cause slippage as the motor tries to engage the tool. So, you might be dealing with the same error.

All that you need to do here is to check on the direction switch. Your first move should be to properly engage this switch and then check for hardware issues.

If the hardware is in good shape, then the simple adjustment to the direction switch will be more than enough to help you here.

On the other hand, if you’re not able to get any response out of the unit and the switch seems to be in rough condition, then you need to get a new switch assembly.

The upside here is that the replacement is not that expensive, and you will be able to get a fresh one on a minimal budget.

From there, you can go about installing the new switch, and you will not have to deal with the same errors down the road.

Hopefully, all the errors will be addressed right here, and you will not have to bother with more complications.

- Check Contact Points

At this stage, you should also check on the contact points for possible errors.

There might be something wrong with the engagement of the connection points, and rust can often gather on these points to create power and performance issues.

So, all that you can do here is to check up on the contact points and fix them accordingly to avoid more issues down the road.

It might take a bit of your time, but you’re not left with many options here. All that you need to do is to make sure that the contact points are clear from rust and that the unit has power.

You can’t expect the unit to work when the issue is with the contact points. So, you will have to address the situation accordingly to avoid more issues with the power supply down the road.

- Blast The Unit With Compressed Air

Next, it is not a bad idea to blast the impact driver with compressed air. We all know that the situation around the workshop can get a bit rough at times.

You will not be able to get anything out of the unit when it is clogged up with debris and gunk. So, be sure to keep that in mind when you’re struggling.

It will barely take you a few moments to get rid of the debris if you follow this routine once every week.

Moreover, the performance of the impact driver, as well as the battery timing, will be much better when you’re keeping track of the maintenance.

A good thing to do here is to ask the professionals working the official support channel to help point you in the right direction.

There is no harm in seeking pointers from professionals, as they can guide you on how to best take care of your DeWalt system.

So, all that you need to do is to keep the unit clear of debris and gunk. That will be more than enough to help you address these issues, and you will not have to deal with more complications again.

Ideally, all errors will be addressed right here if the hardware itself is not damaged with the DeWalt impact driver.

- Get it Checked

Lastly, if nothing so far has worked out for you. There might be something wrong with the wiring, or some other component, such as the impact motor, might have gone bad.

It is better to get the impact driver thoroughly diagnosed by a DeWalt-authorized technician, and that should help you out.

You will not have to worry about a single thing afterward for sure. They will be able to check if some wire has broken, some connectors might not be connected properly, or the motor might have gone bad.

So, you should ensure that it is fixed up properly, and that will sort out the problem for you perfectly.

Wrapping Up

Most of the time, you will just have to follow through with these pointers to get ahead of minor complications with the DeWalt impact driver not impacting.

Ninety percent of the time, you will be able to avoid these issues by keeping track of basic maintenance requirements.

However, if you have been using the unit for a long time and it is in good shape, then the problem is more likely related to a drained battery.

There is not much else that you can do except to change the battery and clean up the connection points.

From there, you need to move forward with inspecting the switches to isolate the issue with the unit not working properly.

Sometimes, changing the switch assembly is the right move, and you have to make sure that the motor is engaging properly. Ideally, you will be able to fix the issues yourself.

However, if you’re not sure about the hardware side of things and the unit seems to be in poor shape, then we suggest that you get your unit fixed by an expert.

All of these errors will be covered by the warranty, and you will not have to go through all of these errors on your own.