Electric Chainsaws are particularly great to have since the added weight of the battery adds more stability for you on the chainsaw for handling it right, but that is not all.

You will also enjoy it a lot more with it, and it allows you a cleaner cutting experience at the same time.

While the power from this unit might not be as robust, you will still be served with the ideal performance from this unit when working on lighter projects.

This system is more suited for beginners or any customer who is aiming to get through DIY projects.

With that said, you might run into a few errors here and there when working on demanding projects. The power will not be able to match up to the robust performance maintained by the chainsaw.

So, be sure to rely on the experts when you’re stuck in these errors.

Since there is no gasoline or any other fuel required, you will easily be able to use it for any of the cutting needs that you might have. So, a few ways for you to be fixing if the electric chainsaw oiler not working are:

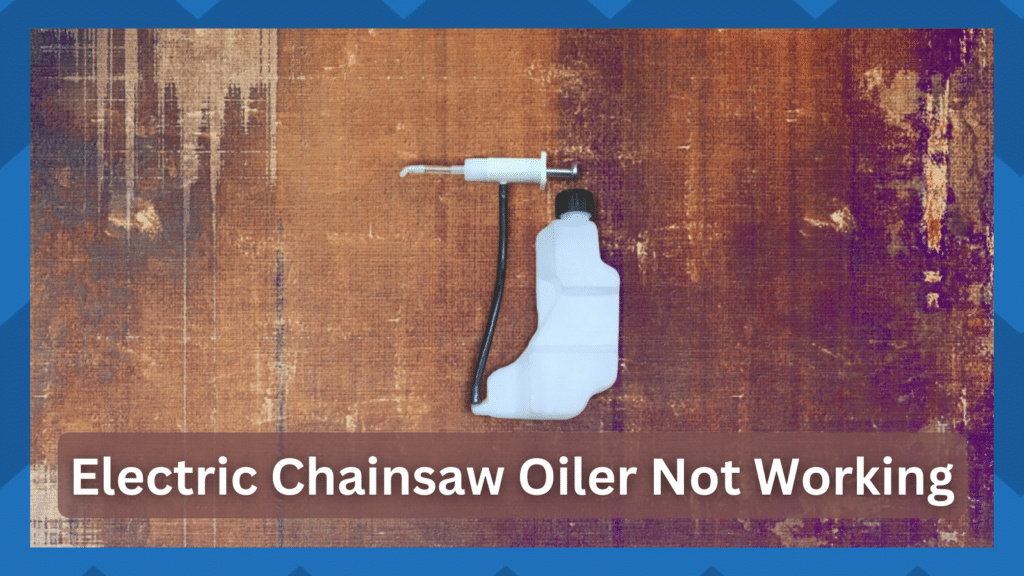

Electric Chainsaw Oiler Not Working

- Check the Type of Oil

The first thing that you will need to make sure of is that you are using the right type of oil on it. There are multiple oil types that you might be finding out there in the market.

However, for these electric chainsaws that have an auto oiling feature on them, you will need to ensure that you are using only the oil type that is recommended by the manufacturer.

If the oil is a bit thick or thin or has any other issue with it, it can cause your system to not work in the right manner, and the oiler will not work.

- Check for Clogging

Another thing that you will need to be careful about is clogging.

There is a lot of sawdust that you will be getting, and if some of that gets inside the container where you put your oil, that might be causing you to have these issues.

That is why you will need to make sure that you are checking on the clogging inside the container.

Not only that, but you also need to disassemble the line that might be used with the container to propagate the oil, and that will allow you to get the proper solution to this problem at the same time.

You need to clear out those lines, and after that, you will be able to make it work for the oiler.

- Check the Wiring

You also need to check on the wiring to ensure that the auto oiler on your electric saw is getting the right power to be working.

At times the wiring might be damaged or have some other problem on it that could be the reason behind this Make sure that you are checking on the wiring.

This will help you to ensure that you don’t have to face any such problems with the oiler at all.

- Check Fuse

For most of the electric saws, there is also a fuse for the oiler, and at times it might be blown due to some of the reasons.

That is why you will need to ensure that you are checking on the fuse as well, and if it is blown, you will need to get the fuse replaced, and that will optimally solve all such problems that you have been facing earlier with the oiler not working.

- Refill The Tank

Sometimes, all that you have to do is check on the tank. Most of the time, the situation with the tank will lead to more complications, and you will have to make sure that the tank is filled up properly. From there, fixing the oiler will come easily to you.

Having no or minimal oil in the tank will never serve you well. While it is not that good of an idea to keep the tank full all the time, you should also make sure that the tank never goes below the 30 percent limit.

That way, you will be able to avoid more complications with the system.

All that you will have to do here is to get rid of the existing oil, clean up the tank, and then pour in the new oil. This simple change will have you sorted out right here. You will not have to struggle with as much hassle, and the system will start responding.

So, be sure to follow through with the refill, and that will help you with the situation. Hopefully, you will not have to worry as much about the situation.

- Check The Pump

At this point, we believe that you are just dealing with a defective pump. If you’ve not been able to get a good enough response from the unit, then your pump might just be defective. You will have to reach out to the dealer to help you out in those cases.

However, before you do that, it is a good idea to check up on the power issues first. You have to make sure that the power going into the system is optimal and that there are no wiring issues.

If you can’t find there to be any power at the pump, then the issue should be more linked to the wiring.

Those types of issues will be sorted out rather quickly when you fix the loose connections and get rid of the damaged wiring. From there, you can check up on the pump one more time, and it should help you with the oiler.

However, if that is not the case, and the pump is damaged, then you need to just get a new one. The upside here is that the pump replacement is rather cheap and will not set you back a great deal.

So, be sure to spare some budget to get your hands on a new pump.

- Check For Hardware Damage

Checking up on the hardware is just as decent an idea. The holes in the system might just be out of shape or forced shut because of excessive pressure. They might not be clogged but rather deformed under rough operating conditions.

If that is the case, and you’re not getting any responses from the unit, then you should take the system to a local repair center. You will have to rely on an expert to help you get the form in a proper manner.

So, if you8’re stuck, just free up the holes and then check up on the performance one more time.

Otherwise, you will just remain stuck in these errors and won’t be able to find a fix. All it takes is a bit of effort on your end. There is no need to go through all of this hassle, and you can just reach out to the experts for help.

- Go Through A Quick Maintenance Cycle

Lastly, even if the rules seem to be deformed, there is no harm in going through a quick maintenance cycle. You have to make sure that nothing is clogging up the system and that the response from the system is optimal.

All that you have to do is to make sure that the oiling holes are free, the pump is not clogged, and the type of oil is ideal. Keeping track of these simple pointers will serve you well in the long run, and you will not have to worry about as many errors down the road.

Ninety percent of the time, a quick maintenance cycle will help you get a better response out of the system. However, if the hardware damages are too severe, then you’re out of luck.

We will suggest that you reach out to the official support team for your brand and have the dealer give you a fresh piece.

Wrapping Up

You can’t expect any performance out of the chainsaw when the oiler is malfunctioning. Sadly, this is a common problem with the electric chainsaw.

So, you can expect to run into the same errors with the chainsaw oiler not working from time to time.

The good thing here is that fixing these errors is not that hard. You just have to check on the system for clogging issues and change the type of oil. These simple methods will be more than enough to help you tackle most errors with the system.

Once that is done, and you’re sorted out, you can move forward with the wiring adjustment. All that you’re trying to do is to change the wiring and then check up on the fuse.

Hopefully, that will help you narrow down the situation with the oiler not working.

Lastly, you might just be dealing with a defective saw. In that case, you will have to reach out to the dealer and have him guide you through the rest.

The dealer will be more than happy to help you out, and you will not have to deal with as much hassle.