There are not only the bigger tools that you need to consider while you are using them for making it work for any projects that you could possibly have taken on.

There is also a lot more that you will have to deal with, including some smaller tools for more precision and accuracy.

It will help you out just fine in order to make sure that you are not getting any errors or inconveniences with the work that you are dealing with.

That also includes the application and utility and the smaller working needs you might have for accuracy and precision that you might have been seeking to make it work in the right manner.

That also includes a center punch that you can use to easily have a positive grip and better handling on the tool, and with the compact size, you might have your concerns with the handling.

Yet, the brushed design will help you to make it work even with the smallest applications you might have.

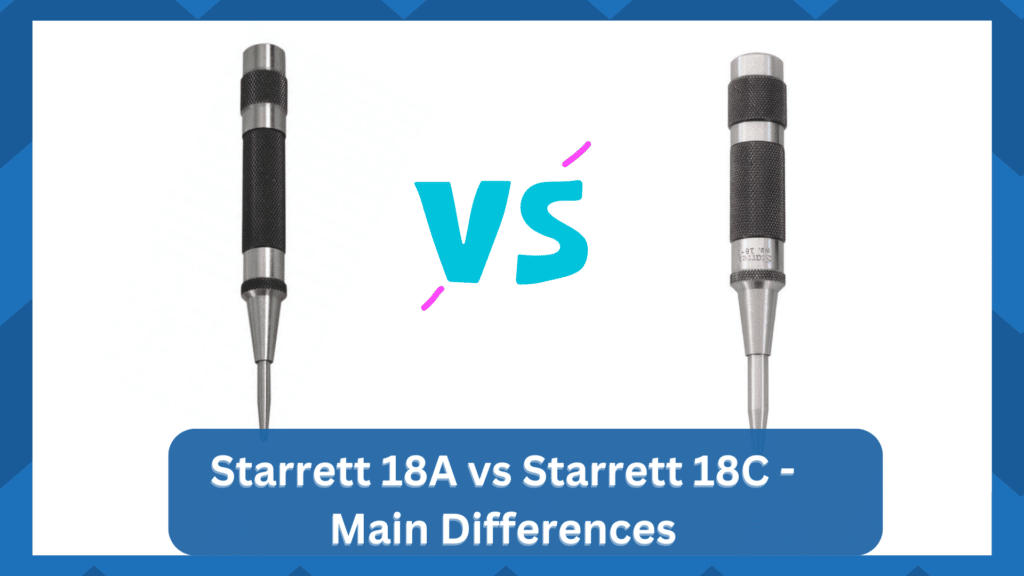

Starrett 18A VS Starrett 18C Main Differences

Starrett 18A and Starrett 18C are two such rugged automatic punches that have steel handles and parts that will help you to have the right power that you might need for any such punching needs.

They have a durable internal mechanism that works automatically for you to have a smooth and seamless working experience among all the different applications you could possibly need.

| Specifics | Starrett 18A | Starrett 18C |

| Length (mm) | 125 | 130 |

| Dimple | 14 mm | 17mm |

| Material | Steel | Steel |

| Manufacturing | America | America |

Every expert and dealer knows that Starrett reigns supreme when you’re looking for a robust build.

So, it can be hard to decide when there are more similarities than differences between the options you’re aiming for. The same is true for these two options offered by Starrett.

You will find Starrett 18A to have a minimal adjustment required when you’re dealing with sheet metal.

The size might not be that small when you’re only looking at the dimensions, but the dimple size difference is pretty significant. Moreover, the smaller dimple looks cleaner on most materials.

Similarly, when you’re dealing with something robust, going with the Starrett 18 C is the better idea.

The larger diameter and the robust power brought forward by this system will serve you perfectly in the long run.

Moreover, you can dial down the power to replicate the minimal presence of the 18A.

It all comes down to the type of material you’re planning on using. There is no point in going with 18A if you’re an expert and need to get through some demanding project.

We all know that having a device that can be dialed down is far better than a device that can’t be scaled up.

So, you can keep in mind that the 18C can work with demanding projects and then can be dialed down to fit delicate or precise adjustments.

However, you can’t rely on the 18A for demanding projects. So, be sure to keep that in mind and figure out what exactly will be the use case for this tool.

From there, it is not that hard to figure out which option will serve you better.

As far as the other pointers are concerned, you will enjoy phenomenal quality, performance, handling, and price point with both options.

Here is some background on these devices to help you pick your favorite one.

Starrett 18A

18A is one such tool that you get to enjoy for all the different applications, and you can easily use it for a number of different parts-related needs that you could have.

18A is 5” in length, and you will definitely be getting the best portability and handling experience with it.

However, with the weight on it, the smaller length is not something that you will be getting the right stability

You will not have to worry about a single thing while you are working with the 18A for any punching needs you might be having.

The punching diameter is 9/16,” and that is something you definitely need to be considerate about and make sure that you are conducting thorough research on that part.

Since the punching diameter cannot be changed and you will only be able to use it to punch for exactly the same diameter that you get on it out of the box.

Coming to the mechanism, you will definitely be enjoying the auto-mechanism, and it strikes the blow when downward pressure is applied to it.

The spring tension on the mechanism regulates the blow for you, and with that in mind, you have the certainty that it will not damage your equipment either.

The dotted pattern on the handle allows you to make it work pretty easily for you for all the different working conditions as well since you don’t have to worry about the tool slipping out of your hands at all.

Starrett 18C

18C is another automatic center punch that you get to enjoy from Starrett, and it has all the basic features that you get on 18A as well to help you out with a far more stable and better experience.

It comes with a bit more length, and you have 5-1/4” of overall length on the center punch that you will be getting, and it definitely adds to the stability of your center punch.

In addition to that, you will also be getting an increased diameter of 11/16”.

With an additional length and punch diameter, you can be assured that you can use it for applications bigger in size than you might have planned for.

It will add the best experience for your working needs at the same time.

The point on 18C can a be easily removed for regrinding or replacement, and you will not have to worry about a single thing when it comes to maintaining your center punch for any needs you could have.

So, it all comes down to the needs you have and what size of holes you are looking to punch when you are choosing between these two.

You can also inquire about the better option by asking a dealer. There is no point in experimenting on your own, and seeking help from the dealer will be the best play.

He will ask you for more details on the type of material you’re using as well as the time and method of use. From there, he will point you in the right direction.

You might even find some options from other robust brands that are just as great.

Wrapping Up

Finding the right tool is not an easy job, especially when your options are from the same brand.

There are not many differences when you’re looking at the same brand for different models. The quality, design, and mechanisms are all the same.

So, if you’re not going through demanding projects, you can’t go wrong with either one of these options.

Similarly, you need to ask the dealer about his opinion. Most experts point towards 18C for robust materials, while 18A is better for thinner options.

You need to figure out the thickness and the type of material that will be frequently used in these projects. If you find it to be thick sheet metal, then 18C is for you.

However, if the diameter is small, then you’re better off with the 18A.

Next, you can also ask the experts available at online fours. These owners maintain years of experience and will surely help you through the purchase.

From there, finding the system will come easy to you as they will help list some of the most viable systems on the market.

Hopefully, you won’t feel the need to switch when sticking with this brand.