People all around the world understand how frustrating it can be to run into a problem with your equipment.

One simple way to get rid of these issues is by contacting a specialist that will help you out. That way, you will not have to deal with the extra hassle of fixing the unit.

Although, this can sometimes take a lot of time, and the specialist will also charge you a lot of money. Alternatively, some people want to fix their devices on their own.

So, it all comes down to how you’re planning on addressing the situation with the unit not working.

Whatever the case might be, the best solution for these issues is to have a set of power tools at your home.

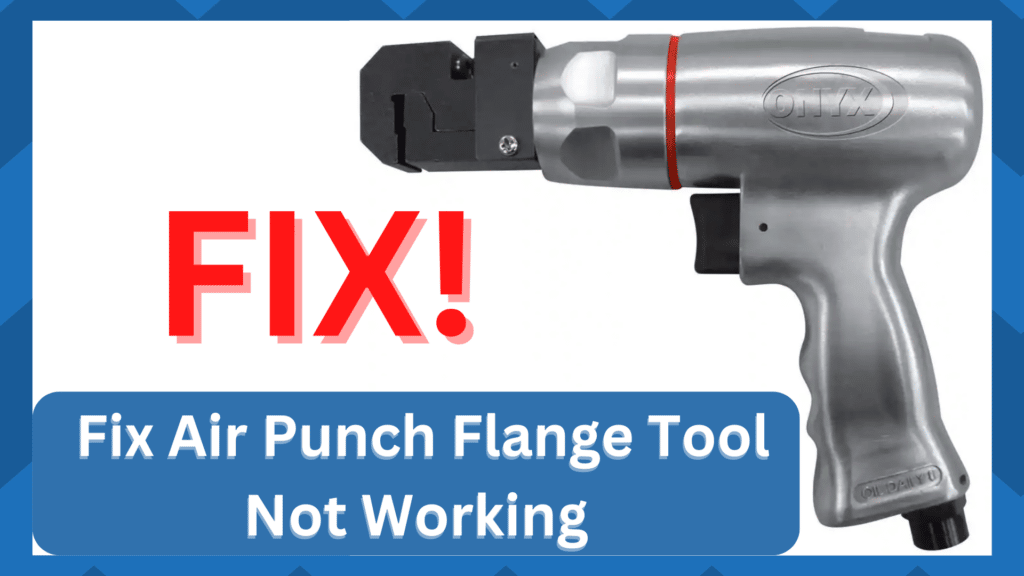

Air Punch Flange Tool Not Working

Talking about this, if you are someone who enjoys modifying cars or doing any other auto body repair job, then having an Air Punch Flange tool can be necessary.

However, recently people have been reporting some issues with this. One of these is that the Air Punch Flange tool is not working.

This is why we will be using this article to provide you with ways to fix this problem.

- Check the Compressor

The Air Punch Flange Tool is an amazing tool that is designed to punch holes in hard materials like metals.

Although, you should keep in mind that the device has some requirements before it can be used. The most important thing is that you have an air compressor connected to it.

This will provide the equipment with enough force to punch holes easily through any material you have put under its jaws.

With that being said, sometimes the problem can also be that you have not tightly closed the compressor pipes.

Alternatively, it can be that your compressor is running low on air. This is why you should first check your air compressor and fix any issues with it.

You should then be able to start using your Air Punch Flange tool without any further problems.

- Oil Clog

Some people use air compressors that are lubricated using oil. Considering this, the oil from these devices can sometimes clog the connection for their Air Punch Flange tool.

You can try taking out the oil to fix this issue. Although, if the device is completely clogged, then the only way to unclog it is by opening your flange tool.

Accessing the internal parts of this device will allow you to easily remove oil from it so that you can start using this device again.

- Check For Leakages

Sometimes, the issue is more with the leakages and the situation with the air pressure. You will not be able to get any performance out of the tool when the air pressure is not managed properly.

So, you will have to make sure that there are no leakages when running into these issues.

The best thing to do here is to make sure that the housing is assembled properly. There should be no alignment issues, and the connection should be tightly secured.

Most of the time that is all that you need to do to adjust the unit. From there, you can also check the unit for damaged components and replace the valve accordingly.

Ideally, the issue will be fixed as soon as you try to adjust the alignment of the unit. So, be sure to keep that in mind when you’re struggling to get a response out of the air punch.

Hopefully, that will be it as long as you’re sure that you’re not lagging behind on the basic maintenance.

So, be sure to check for leakages and go about adjusting the unit accordingly. You will not have to deal with more complications down the road.

- Trigger Issues

Sometimes, the issue is with the trigger and not with the valves or the air pressure.

So, if you’re not getting the desired response from the trigger or have missed a few maintenance cycles over the last couple of weeks, try cleaning the trigger.

All that you need to do to fix the trigger-related issues is to clean around it. There is no need to follow through with more steps, and simply cleaning the trigger will have you sorted in the long run.

Hopefully, you will be able to get a robust response after you blast the unit with compressed air.

Just make sure that the trigger itself is not damaged, and that will be enough to help you get optimal efficiency from the device.

From there, you can go about adjusting the situation with the hardware accordingly.

- Fix Valves

The situation with damaged valves, loose connections, and worn points can also create issues. If you’ve been using this unit for a long period, then now might be a good time to check up on the valves.

You have to make sure that there are no damaged sections. If you do find there to be damaged valves, the only reasonable thing to do is to install a replacement.

There are no quick methods that can help you deal with damaged or defective valves. So, be sure to keep that in mind when you can’t seem to get any response out of the air punch.

You can also test your luck by tightening up the housing assembly one more time.

If that doesn’t fix the issue and the alignment just won’t sit perfectly, then the only thing left is to call the dealer to send you new components.

He will also guide you through the installation and you won’t have to struggle yourself. From there, you can just test out the new valves and go about using the air punch accordingly.

Hopefully, you won’t feel the need to reach out to an expert and will be able to address these complications yourself.

- Try Some Lube

If you do get a bit of a response from the system and the situation with the efficiency is creating issues here, then you need to focus a bit more on getting some lube.

Even if you focus on proper storage of your units, they will not perform well if you use them after months.

This is especially true if you use grease to lube up the pivot points. Over time, this grease can mix up with debris and create a gunk-like consistency.

This issue will only complicate the situation and you will not be able to get a suitable response out of the system. So, be sure to check up on the unit accordingly.

If you do find there to be build-up on the unit, then you need to proceed with cleaning up the gunk and then using some fresh lube from the market.

This will help you get a bit of performance out of the unit without having to deal with more errors.

Hopefully, all complications will be addressed right here. However, you might also be dealing with a defective unit if you’re not getting a response at this stage in the troubleshooting routine.

- Faulty Device

Finally, if your Air Punch Flange tool is still not working, then there is a high chance that the device might be faulty. The only solution, in this case, is that you contact the brand you bought this device from.

Although, before this, you should first confirm that the material you were trying to punch a hole in was not too thick.

If your equipment is damaged, then notify the company about your problem. They should then look into the issue and provide you with a viable solution.

You will either be provided with a replacement tool. If not, then the device is completely useless, and you will have to purchase a new one.

Wrapping Up

Struggling with the air punch flange not working? Just follow through with the pointers listed here, and you will be ahead of these complications in no time.

Figuring out the issue on your own can be hard at times, and it would serve you better to also engage someone from the official support team.

As long as you’re a bit sure the hardware is in good shape, simply adjusting the compressor and checking on the situation with the oil clog will help you through these errors.

So, be sure to start out with these basic maintenance steps, and you will be sorted.

On the other hand, if you’re not as lucky and the issue with the unit persists even after going through these pointers, and you’re not that sure about the hardware, we suggest that you get in contact with the dealer.

There is a good chance that your current unit is defective or damaged. The only thing that can be done to deal with damaged units is to replace them entirely.

You can’t rely on any quick fixes, as these units are bound to run into more issues down the road.

So, be sure to check up on the hardware again when you get no response after trying out the methods in this guide.