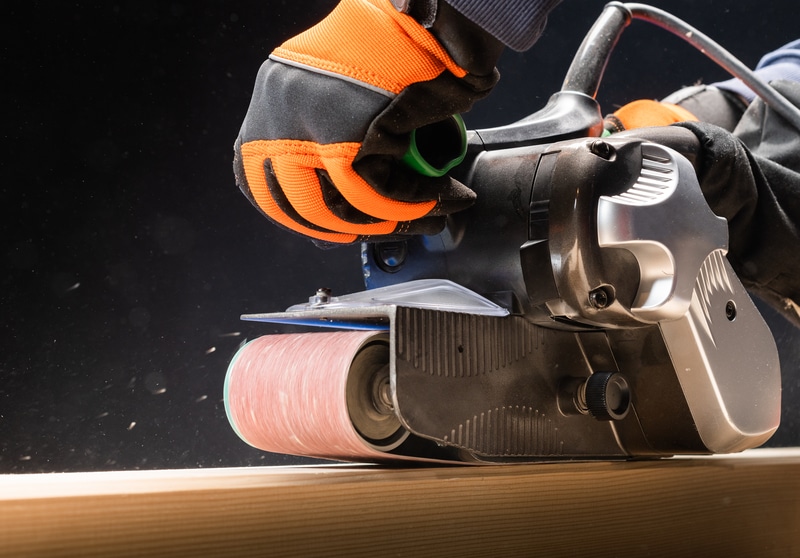

If you’re looking for efficient and light belt sanders for your private projects, then you can rely on brands like Tacklife and Makita.

Both of these brands focus extensively on enabling customers with premium units that last for an extended period of time.

So, if you don’t know much about belt sanders, going with these brands is a safer option for you.

There is simply no gain in wasting your money on cheaper units that don’t bring any consistency to your setup.

You will only save a bit of cash in the short run and will end up spending more over the years. For this reason, it is always better to go a bit above the budget on the initial investment.

How To Fix Belt Sander Belts Keep Breaking?

You will not only save money on the upgrades, but you will also enjoy a more robust response out of the belt sander. So, keep that in mind when you’re aiming for ideal performance out of the belt sander.

With that said, a common issue that users often experience with belt sanders is that the belt keeps breaking after minimal use.

If you’re dealing with a similar problem, then the following solutions should help you overcome this problem.

- Check Tension

The first thing that you need to check is the tension in your belt sanders. Ideally, you won’t have to worry about changing the belt for an extended period.

However, if the tension in the belt sander is not managed properly, the belts will keep breaking at a much faster pace.

So, if you’re struggling to get the desired hours of performance from your unit, you should start by checking the tension in your system.

If the tension in your belt sander is too much, then call your dealer and have him fix the unit for you. Most of the brands cover these issues within the warranty policy.

So, make sure to call customer support and explain your situation to them. That way, the belts will last for a much longer period after the tension in your unit has been managed.

- Manage Temperature

Using the sander for an extended period of time heats up the belt, causing it to break faster.

So, if you’re working on extensive projects without any breaks, then that is likely why the belts on your belt sanders keep breaking.

Luckily, you can overcome this issue by managing the temperature and taking a few breaks in between projects.

Along with that, if you like to purchase sanding belts in bulk, managing the stock in colder spots should help you extend the life of the belts.

So, you need to keep the temperature aspect in mind while purchasing sanding belts from the market.

- Poor Sanding Technique

Many experts have pointed out that users press down on the sanding belt too hard, creating excessive friction and heating up the sanding belt.

If you are new to using a belt sander, then there is a good chance you’re using the belt incorrectly.

Because of the increased friction between the belt and the material, the belt keeps breaking before you get the desired performance. So, you need to reach out to an expert and explain the issue to him.

That way, you can get some pointers on how to go about managing the sanding technique to maximize the efficiency of your belt sander while also extending the life of your unit.

For more information, it is always a good idea to seek guidance from a local expert.

So, if you can’t seem to get ahead of any issues with your weekly projects, relying on expert opinion is your best bet.

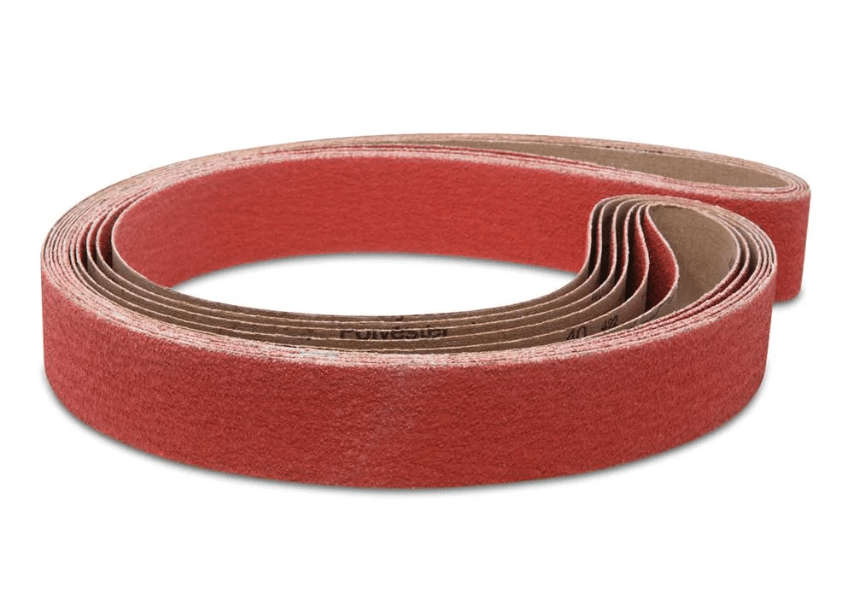

- Use Better Belts

Sometimes, the only reasonable thing that you can do is to upgrade the system, and there are no quick methods around it.

You will have to find some better brands that offer more robust belts. So, you will need to only purchase from brands like Skil when browsing some upgrades for your sander.

These options will not exactly be cheap, but when you look at the value and the convenience, they will be far better than any other option on the market.

It all comes down to how you’re planning on addressing the situation. Spending a bit extra in the short run for a better life span and efficiency will have you sorted for several projects.

So, be sure to stick with this option and try out the relevant belts to avoid issues down the road. You will not have to deal with the same complications again.

Otherwise, you can go cheap and end up spending more in the long run when the sanding belts keep breaking again and again.

Hopefully, these pointers will help you get the right performance out of your system, and you will not have to struggle with more errors on your end.

- Check The Direction

If you’re already using some pretty robust sanding belts and taking reasonable breaks in the middle of the project, then the next thing that you need to check is the direction of the belt sander.

The belts are designed to only work in a certain direction only. You can’t just install these belts at random, and you will have to put more focus on finding the right direction.

The majority of belts will have arrows printed on them, indicating the proper operations of the unit.

You can be mindful of these arrows and use the sander in that direction as well to avoid complications down the road.

Otherwise, you will get stuck in these issues and won’t be able to get any response out of the sanding belt.

If you’re not sure about the installation or are new to the market, try asking an expert for a practical demonstration.

He will make your life much easier, and you will not have to struggle as much with the sander.

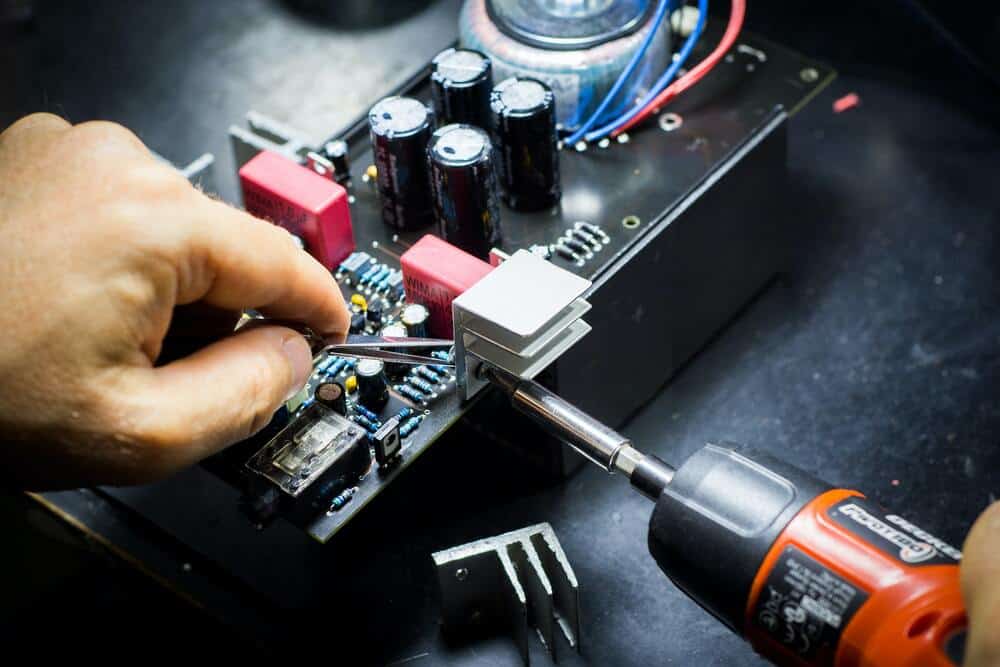

- Check For Sander Issues

It is also possible that the issue is with the sander and not the belt. Imperfections on the unit, some broken sections, or rough surfaces will only lead to issues with the belt getting damaged over time.

There are no quick fixes as you’re trying to deal with the sander. So, the only thing that you can do is to check up on the belt sander itself for hardware issues.

If you find there to be hardware issues, then you have to reach out to the dealer about these problems. The warranty should cover all of these issues.

This is especially true if you believe that you got a damaged unit out of the box. So, if you’ve just got your hands on a fresh piece, just ask the dealer to guide you through a fix.

He will take charge of the situation and try to help you address the issue. On the other hand, if you both come to the point that the unit is defective, then you can demand a replacement.

After the claim has been verified, you can expect to get the new piece within the same week.

- Ask The Experts

Lastly, you can bring this issue up with the official support team from the belt sander brand that you’re using.

They will help you get a better understanding of the issue and will recommend suitable sanding belts for that specific unit.

If you’re lucky, the situation will be addressed right here, and you will not have to deal with more complications.

However, if the situation is a bit more severe with there being issues with the belt sander itself, then you can’t do much about the situation.

The best you can do is to get pointers on how to improve the performance of the unit and modify your technique.

So, if you find that there are no issues with the hardware and you’re following all of the points listed here, then be sure to get help from a professional directly.

Here, you can also reach out to your local experts to help you with some sessions. He will show you how to best manage the belt sander without dealing with more complications down the road.

Hopefully, that will be it, and you will not have to deal with more complications on your end.

Wrapping Up

Struggling to fix the situation with the belt sander belt keeps breaking? Follow through with the details listed here, and you will save yourself a lot of hassle.

Most of the time, you will be able to limit these issues by reducing the pressure and taking some breaks.

This will help the sanding belt cool down as you’re trying to get through your projects. From there, you should also focus more on precision and don’t feed too much material all at once.

That will help you get a better response out of your belt sander.

Lastly, you need to also check the installation of the belt sander. If you’re not installing it correctly, it will just get damaged as it rotates in the wrong direction.

So, be sure to learn the proper installation and then check the performance of the new belt one more time.