There are appropriate tools for getting each job done today and that makes the task at hand easy, and you can get it done more conveniently and in a better manner if you know the right tool for the job. Not only it makes the task easy to know the right tool for the job, but it will also help you gain the right accuracy and precision that you might have been looking for if you know how to use the tool incorrect manner. Bandsaw is one such tool that has a platform on it and it goes through that. The blade is mounted on the top and it moves vertically to cut the workpieces that you put through the bandsaw.

Yet, there are several factors on the bandsaw that you will need to be looking at and that allows you to make an accurate decision regarding choosing the best equipment that would suit your needs perfectly, and with that you can get the job done in a better manner at the same time. There are two types of guides that are mostly used on the bandsaw and they are guide blocks and guide bearings. A brief account of them both and the key differences between them would be:

Bandsaw Guide Blocks vs Guide Bearings:

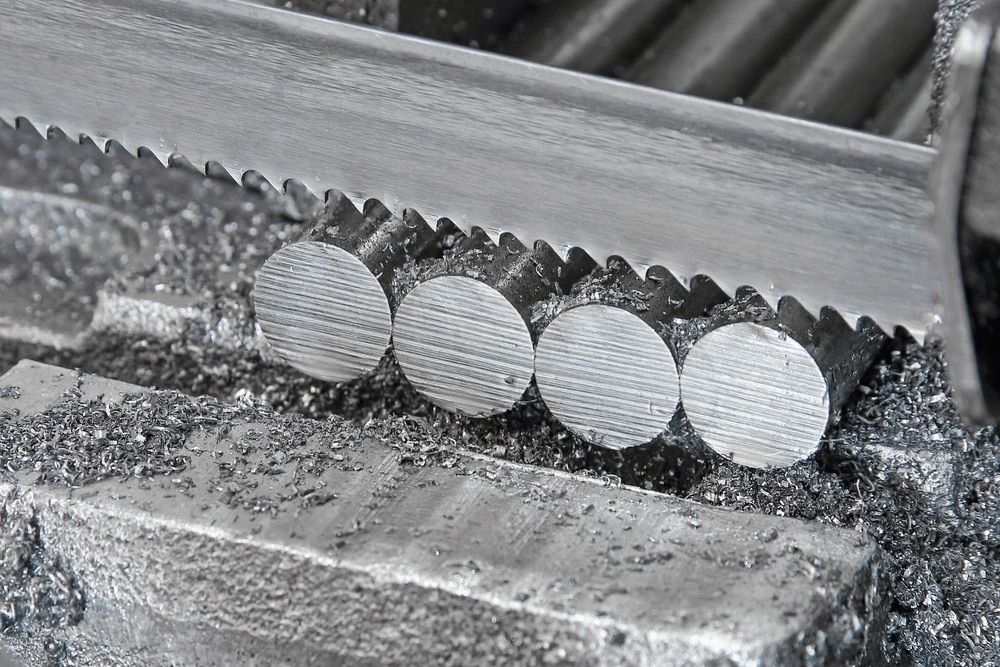

Bandsaw Guide Blocks

Guide blocks are blocks as the name suggests and they are designed to be in the square or rectangle form. There are quite a few metals that are being used for the applications since the guide blocks have to ensure proper accuracy for the blade on the bandsaw that you might be using. With all that, the main purpose is served and you get the perfection of getting the bandsaw blade focused at one point as you would want to.

Yet, moving forward it would also matter greatly to know that the guide blocks that are being used on the bandsaw are designed as such to get the blade lubricated without getting it oily, and with that, the blade doesn’t only resist the friction, but it also helps the blade to remain cooler. Yet, the guide blades are square and that is bound to create a bit of friction. That is why you will need to keep an eye on the blades regularly and ensure that you are getting them replaced since they are bound to wear with the usage and that will affect your accuracy on the workpiece. Not only that, but they can be deformed as well due to excessive heat, and need cooling time after several minutes of usage to ensure that they are not getting too hot and causing you any problems while you might be using them.

Bandsaw Guide Bearings

Guide Bearings are another innovation that has solved a number of problems that were there due to using the guide blocks on a bandsaw. Starting on that, the guide bearings are ball bearings that are round and since they will roll with the bandsaw blade, there is a lesser amount of friction generated between them, and if you manage to keep them lubricated right, it will get you the least bit of friction. That is why, most of the users who have commercial or extensive applications for their bandsaw, would prefer the guide bearings any day over a regular guide block.

In addition to all that, you also get to enjoy more accuracy and precision with these guide bearings since there is minimal wear and tear on them due to the friction and they are likely to be working perfectly for longer periods as compared to the Bandsaw guide blocks. That certainly means a lot and you will not have to worry about getting them replaced due to the most common issue on the guide blocks that they can be deformed due to heat.

Since the guide bearings on the bandsaw are also not getting much temperature, you can continue your work constantly without giving them many breaks and that is definitely something that matters a lot if you are looking to be using the bandsaw for longer hours of work, and you don’t want to just sit idle during the work, waiting for the guide blocks to be cooled down.